SMS code login

Password Login

Get SMS verification code

Get SMS verification code

2025-12-26

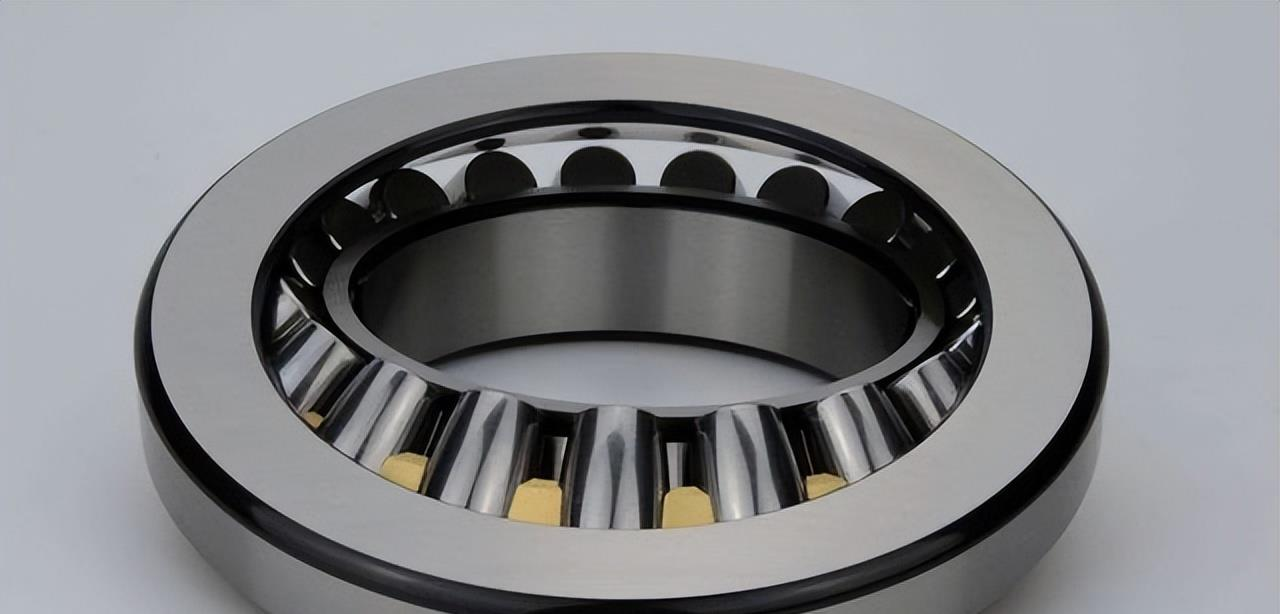

In traditional perception, bearings are almost synonymous with metal components. However, as industrial scenarios demand higher performance in terms of lightweight design, noise reduction, corrosion resistance and maintenance-free operation, engineering plastics and advanced composite materials are "invading" the bearing field at an unprecedented speed, ushering in a quiet yet profound transformation.

High-performance engineering plastics such as nylon, polyoxymethylene (POM), polyimide (PI) and polytetrafluoroethylene (PTFE), with their self-lubricating properties, excellent chemical stability and low-density advantages, have become ideal choices for medium-to-low speed, oil-free lubrication or humid and corrosive environments. Especially in food processing, pharmaceutical and water treatment equipment, they not only avoid the risk of lubricating oil contamination, but also significantly reduce operating noise and improve the cleanliness of the whole machine.

Composite materials based on PTFE and reinforced with glass fiber, carbon fiber or bronze powder are widely used to manufacture sliding elements such as spherical plain bearings and wrapped bushings. These materials can work stably for a long time without external lubrication, greatly reducing maintenance costs, and have shown strong vitality in automated equipment, agricultural machinery and outdoor facilities.

Structural ceramics such as silicon nitride (Si