SMS code login

Password Login

Get SMS verification code

Get SMS verification code

1. High quality raw materials

2. Famous suppliers of raw materials in China

3. Rigorous supplier approval and testing procedures

4. Strict incoming inspection procedures

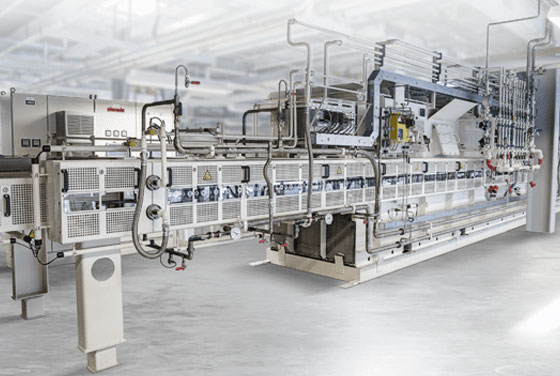

XIR has invested millions to introduce a world-class AICHELIN roller hearth furnace heat treatment production line. It has the following significant advantages:

1. In the operation mode, the lifting table is used to connect the materials, so as to prevent the product from bumping.

2. It has good sealing performance, and the workpiece after quenching does not appear oxidation and decarburization. After quenching, the surface of the workpiece presents light blue, uniform color and luster.

3. After quenching, the hardness of the workpiece can be stable in the range of 58-63 HRC, and the hardness difference of single workpiece is not more than 1 HRC, and the hardness difference of the same batch of workpiece is not more than 1.5 HRC.

4. The dimensional stability of the product can be improved after the workpiece is quenched in the production line. It also makes the products have good comprehensive mechanical properties and prolongs the service life of the products.

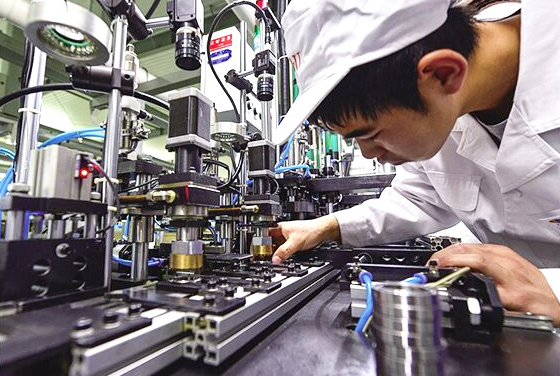

1. Optimize the layout of production workshop according to the production line mode.

2. In the operation mode, the lifting table is used to connect the material, so as to prevent the product from bumping.

3. Totally enclosed constant temperature production workshop.

4. Adopt statistical process control system.