SMS code login

Password Login

Get SMS verification code

Get SMS verification code

2024-07-05

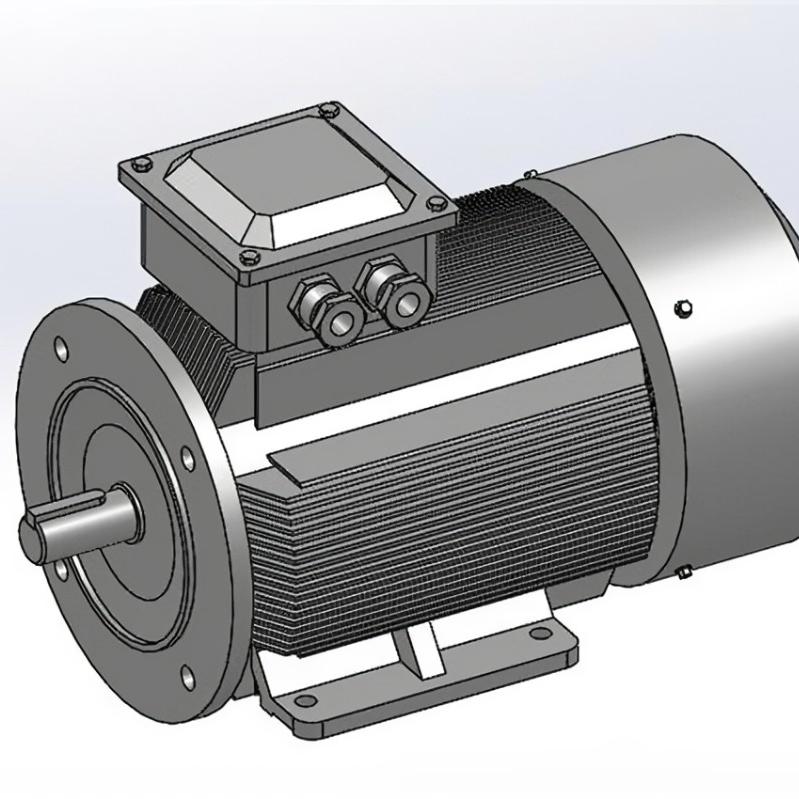

The motor is the most problematic part in the reliability accident report of rotating equipment. Since 40% to 70% of motor failures are related to bearings, it is not surprising that the key to maintaining motor quality lies in bearings. Energy efficiency is another key factor in motor applications. This also largely depends on the choice of bearings. But choosing the right bearing is not enough. How to install, lubricate, handle, and maintain the motor is also critical to the performance and life of the motor. XIR works closely with motor manufacturers and end users. From innovative engineering services from the design to installation phase, to monitoring systems and services that drive the reliable and efficient operation of your motors.

Large-capacity, generally off-the-shelf catalog motors are small and medium-sized equipment, usually 1 to 500 kW. All general-purpose motor types have one thing in common: their energy efficiency, reliability and trouble-free operation are critical to productivity. Electrically insulated bearings are our offering in addition to seals, standard bearings and grease products to protect your motor from stray currents, help improve motor performance, maintain equipment profitability and reduce long-term costs.

As the name suggests, application-specific motors are primarily designed to meet application-specific requirements and conditions. In many cases, record motors can be modified to meet specific requirements. However, as with standard solutions, reliability and trouble-free operation are critical.

Our bearings, seals and lubrication solutions for application-specific motors help improve motor performance, maintain equipment profitability and save long-term costs. Contact an XIR application expert for help in finding the right solution for your needs.

With the increasing requirements for the accuracy and variable processes of motors, and the increasing concern for energy conservation and environmental protection, motors need to be precise and controllable. XIR offers a range of motor control feedback devices and can be integrated on bearings or mounted on shafts according to application requirements.

For applications requiring compactness and ruggedness, bearing integrated feedback devices are preferred. These devices are common to a variety of applications and can perform a variety of operations.

The XIR sensor bearing unit is equipped with dust-proof sensor and multi-function deep groove ball bearing, which is a mechanical component of mechatronics. The XIR body, pulse ring and bearings are mechanically connected together to form an integrated component that can be installed quickly. Strict tolerances are maintained inside the bearing.

The integrated design helps reduce development time and manufacturing and assembly costs. Robust components and materials also reduce size, weight, and improve safety and reliability.

Belt drive motors are an economical and practical alternative to direct drive. They absorb large amounts of shock and vibration without the need for a gearbox, and can be switched between speed and torque by adjusting the size of the pulley in the belt drive system.

Compared to direct-coupled applications, motors for belt drive applications can withstand a wide range of load bearing conditions. The bearing in the fixed position of the belt drive system is affected by the increase of the radial load of the belt itself, and the risk of misalignment increases. And, since misalignment is one of the most common causes of premature belt failure, the fixed position of a reliable belt drive system requires robust bearings.

We offer a range of products for belt drive motors to simplify installation, alignment and maintenance. So whether you're an OEM or an end user, learn about belt drive application solutions and see how we can help you improve the performance of your motors, maintain the profitability of your equipment and reduce long-term costs.