SMS code login

Password Login

Get SMS verification code

Get SMS verification code

2025-12-26

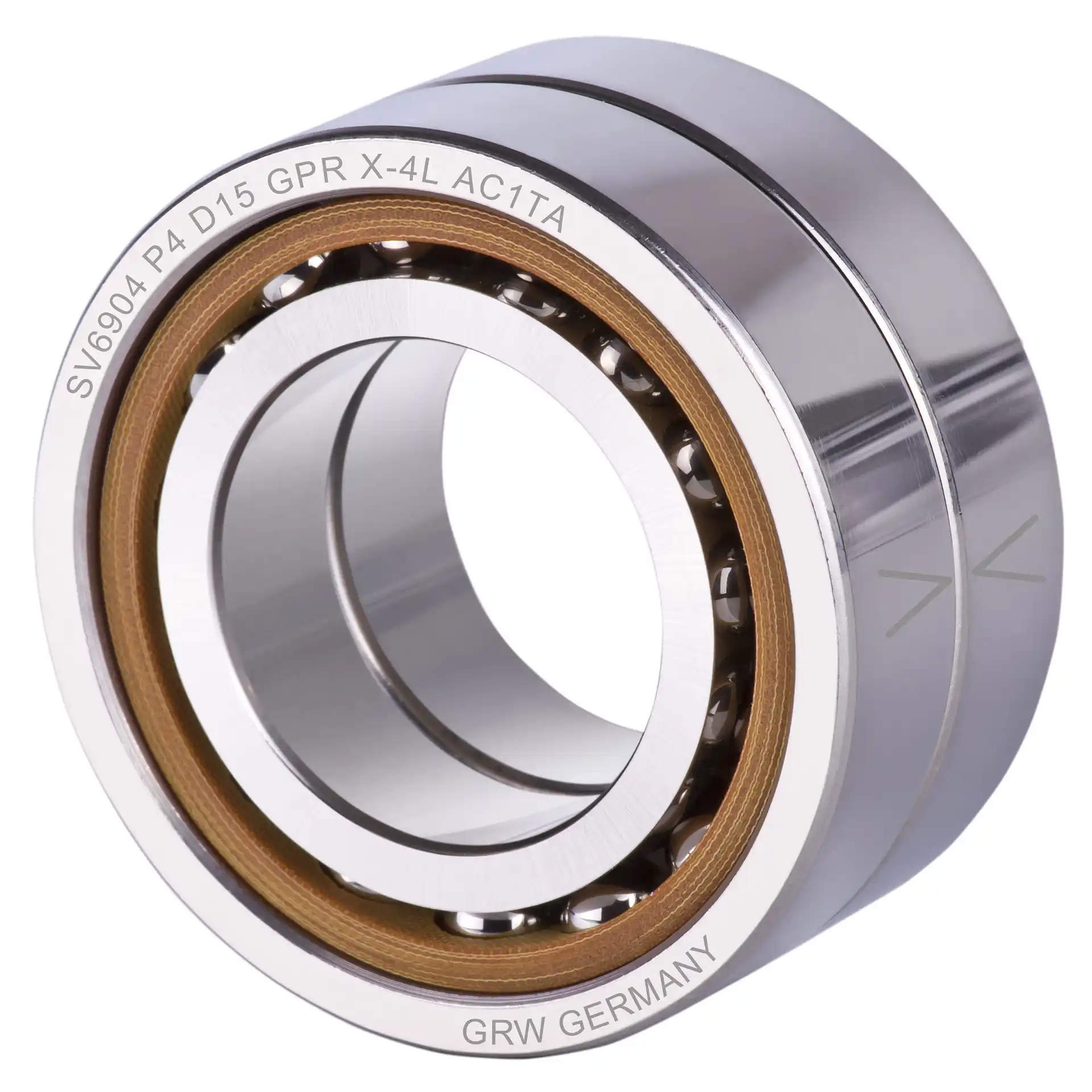

In the modern industrial system, bearings are known as the "mechanical joints", while high-end bearings stand as the "elite troops" among them. As core components featuring high precision, high reliability and strong environmental adaptability, they maintain the stable operation of various high-end equipment by reducing friction and providing precise support. Compared with ordinary bearings, the gap lies in the precision divide between the "millimeter level" and "micron level", as well as the adaptability to "normal working conditions" versus "extreme environments". Simply put, ordinary bearings can meet the basic needs of household motors and small machinery, whereas high-end bearings must tackle the harsh challenges of high temperature and high speed in aero-engines, heavy-load vibration in high-speed railways, and nanoscale positioning in lithography machines. Their performance directly determines the efficiency, service life and safety of high-end equipment.

The outstanding performance of high-end bearings stems from the relentless pursuit of four key indicators, which also constitute the core differences from ordinary bearings:

The achievement of these indicators relies on the collaborative innovation of materials, processes and design. For example, in terms of materials, high-end bearings adopt special materials such as cemented carbide and silicon nitride ceramics. Thanks to technologies like vacuum degassing and hot isostatic pressing sintering, the oxygen content in bearing steel is controlled below 5ppm (equivalent to only 5 oxygen atoms per million atoms), fundamentally avoiding fatigue failure.

High-end bearings have long penetrated every aspect of our lives, though most of them remain "hidden from sight":

Precision manufacturing: The nanoscale positioning masterIn semiconductor lithography machines, IKO thin-walled needle roller bearings, with a radial runout tolerance of 0.01mm, support the wafer stage to achieve submicron-level displacement, ensuring the lithography accuracy of 3nm process chips. The bearings in German Zeiss coordinate measuring machines can control the straightness error within 0.1μm per 100mm, improving the inspection efficiency of aero-engine blades by 4 times.

Transportation sector: The guardian of speed and safetyThe gearbox bearings of China's CR400BF high-speed trains experience a temperature rise of no more than 40℃ at a speed of 350km/h, with dust intrusion reduced by 90%, ensuring reliable long-distance operation. The self-lubricating bearings for the main landing gear of Airbus A350 maintain stable performance in the temperature range of -55℃ to 120℃, adapting to flight operations in different climatic zones around the world.

Extreme working conditions: The challenger of heavy loads and high temperaturesThe bearings of Sany Heavy Industry excavators can withstand continuous impact in heavy-load mining environments. The SKL ceramic bearings used in the metallurgical industry can maintain dimensional stability at a high temperature of 1200℃, solving the problem of softening of traditional bearings. The bearings for offshore drilling platforms, with their excellent corrosion resistance, have a service life three times longer than that of ordinary bearings in salt spray environments.

Livelihood sector: Precision empowerment from medical care to consumer goodsThe robotic arm joints of the da Vinci surgical system are equipped with miniature cross-roller bearings, achieving a surgical instrument control resolution of 0.1mm, reducing the tissue damage rate of radical prostatectomy by 40%. Even in high-end speed roller skates, miniature ceramic bearings can support athletes in 500km of high-intensity training without performance degradation.

For a long time, the global high-end bearing market has been dominated by enterprises such as Germany's SKF and Japan's NSK. China used to import more than 3.5 billion US dollars worth of high-end bearings annually for high-speed railways, aerospace and other fields. The core bottlenecks are concentrated in three aspects: material purity, manufacturing precision and design capability. However, China has achieved key breakthroughs in recent years: Xiwang Special Steel has stably controlled the oxygen content below 5ppm, reaching the world's top level; Xingcheng Special Steel's high-end bearing steel is exported to Japan and Europe, with sales volume ranking first in the world; high-speed railway and wind power main shaft bearings produced by enterprises such as Luoyang Bearing have been put into mass application, and the import dependence has been significantly reduced.

The leap from a "major bearing producer" to a "bearing power" in China is not only the upgrade of individual products, but also the coordinated progress of the entire industrial chain including materials science, precision manufacturing and testing technology. In the future, driven by Industry 4.0 and the dual-carbon goals, with the research and development of new products such as ceramic bearings and intelligent sensing bearings, high-end bearings will evolve towards higher efficiency, longer service life and greater intelligence.